The Green Energy Transition – there is no time to waste

One doesn’t have to be a futurist to envision a future where the planet is powered by green energy – row upon row of wind turbines, solar panels on every roof, and electric vehicles whizzing silently down the road. But while we are well on our way to this utopian future, governments and businesses across the globe are yet to fully tackle the enormous waste that will be generated by these clean sources of energy.

How does clean energy generate waste?

The International Renewable Energy Agency estimates 60-78 million tonnes of solar panel waste will be generated by 20501. The world will also generate about 6 million tonnes of waste generated from discarded solar panels, annually by that point.

According to the CSIRO, Australia produced more than 3,300 tonnes of lithium-ion battery waste in 2020́. This figure is expected to exceed 136,000 tonnes by 20362. Australia currently recycles 98% of lead-acid batteries but only 10% of lithium batteries. If disposed of incorrectly, such as in landfills or waterways, lithium batteries can cause contamination and could pose fire and explosion risks3.

Wind turbine blades are made of durable yet expensive materials like carbon fibre or glass fibre composite. These blades are built to withstand hurricane-force winds and, as a result, the blades can’t easily be crushed, recycled, or repurposed. Estimates suggest there will be 43 million tonnes of blade waste globally by 20504.

All of this is to say the quantum of waste generated from green energy sources will be enormous and could overwhelm our existing waste management systems in the absence of feasible solutions.

The problem is not that these products cannot be recycled, rather it is about the cost and effort involved. The process is expensive and time-consuming, and the value of the extracted materials is often not enough to cover the costs of extraction. Add volatile material prices, new battery technologies, and a lack of standardisation into the mix and we have little economic incentive for setting up new recycling facilities. Despite this, governments, research institutions, and private enterprises are ramping up their investments into developing new recycling technologies.

Existing technologies for recycling in the green energy supply chain

Solar panels – the ‘glass’ may not be greener on the other side

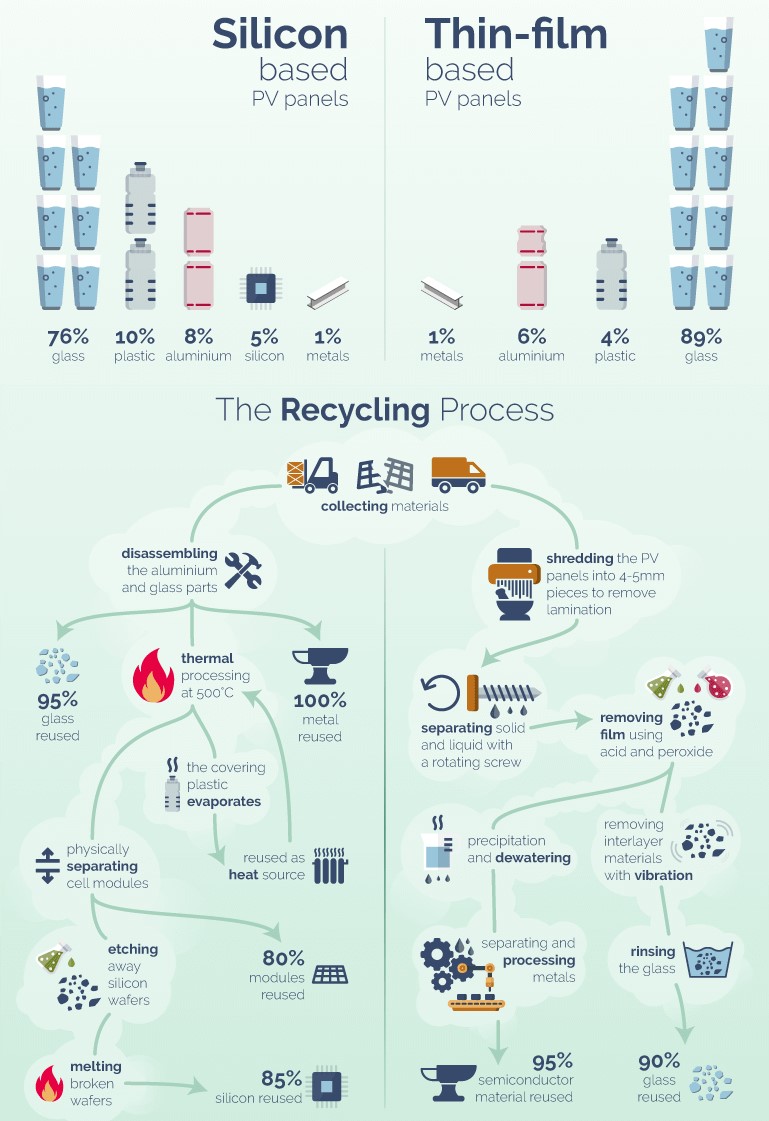

Solar panels look like sheets of glass, but they are complex products, made of silicon solar cells, aluminium metal frames, glass sheets, copper wires, and plexiglass. On a standalone basis, each of these materials should be easy to recycle, but the process of separation is tedious and expensive. The current process involves the removal of the aluminium frame and separation of components

The current process involves the removal of the aluminium frame and separation of components before shredding the photovoltaic cells, followed by chemical processing and electrolysis to separate the materials. Another process applied to thin film panels involves shredding the entire panel into tiny pieces and running chemical processes to separate the materials. Both methods are explained in the infographic below. Both methods are explained in the infographic below.

Source:https://www.greenmatch.co.uk/blog/2017/10/the-opportunities-of-solar-panel-recycling

Lithium-ion batteries / EV Batteries – repurpose or recycle?

Over time, the expected range and power of an EV battery may diminish to 70-80% of its original capacity, potentially requiring replacement. However, these batteries still have enough capacity for them to be repurposed for less-demanding applications such as energy storage. Several retired EV batteries could be put to use in large-scale deployments to store electricity. For example, Korean automaker Kia has announced a partnership with Deutsche Bahn to repurpose retired EV batteries to create scalable energy storage systems, with a prototype in use in Germany5.

With the cost of new lithium-ion batteries forecast to decrease, the reuse value proposition is threatened6. Furthermore, the repurposing process is labour-intensive, involving manually removing batteries from vehicles, testing and refurbishing them if required, before redeploying. The process is difficult to automate as there are many battery-pack designs varying in size, electrode chemistry and format (cylindrical, prismatic, and pouch).

While repurposing EV batteries could extend their useful life by 5-8 years7, eventually these batteries will have to be recycled.

Pyrometallurgy (separation at high temperatures) and hydrometallurgy (using water-based acid or alkaline solutions) are the top two current methods. Both techniques involve mechanical and chemical separation stages which may be used alongside intense heat or chemicals. Pyrometallurgy is energy-intensive, emits toxic gases, and cannot recover some valuable minerals, including lithium. Hydrometallurgy can get at materials not easily obtained through burning, but it uses harmful chemicals posing health and environmental risks. All of this comes at a cost: by one estimate, the cost of recycled lithium is five times that of newly mined lithium8.

Wind turbine blades – not quite gone with the wind

Wind turbine blades have a life span of about 20 years and are expensive to break down due to their size and composition – they are typically manufactured using a mixture of glass fibre, carbon fibre, polyester, and epoxy resins.

Current recycling methods are complex and involve separating the materials, with the resins being used for energy production while the fibre composites are reused. Despite the challenges, a number of blade manufacturers and recyclers in Europe and the US have announced plans during the last two years to explore recycling options. For instance, glass fibres from the blades can be recycled into cement. Energy companies in Denmark have used old turbines to construct bicycle shelters and playground equipment.

Wind Turbine blades repurposed as bike sheds. Source: https://www.architectureanddesign.com.au/news/danish-wind-turbine-blades-repurposed-as-bike-shed#

Recycling renewables – what’s on the horizon?

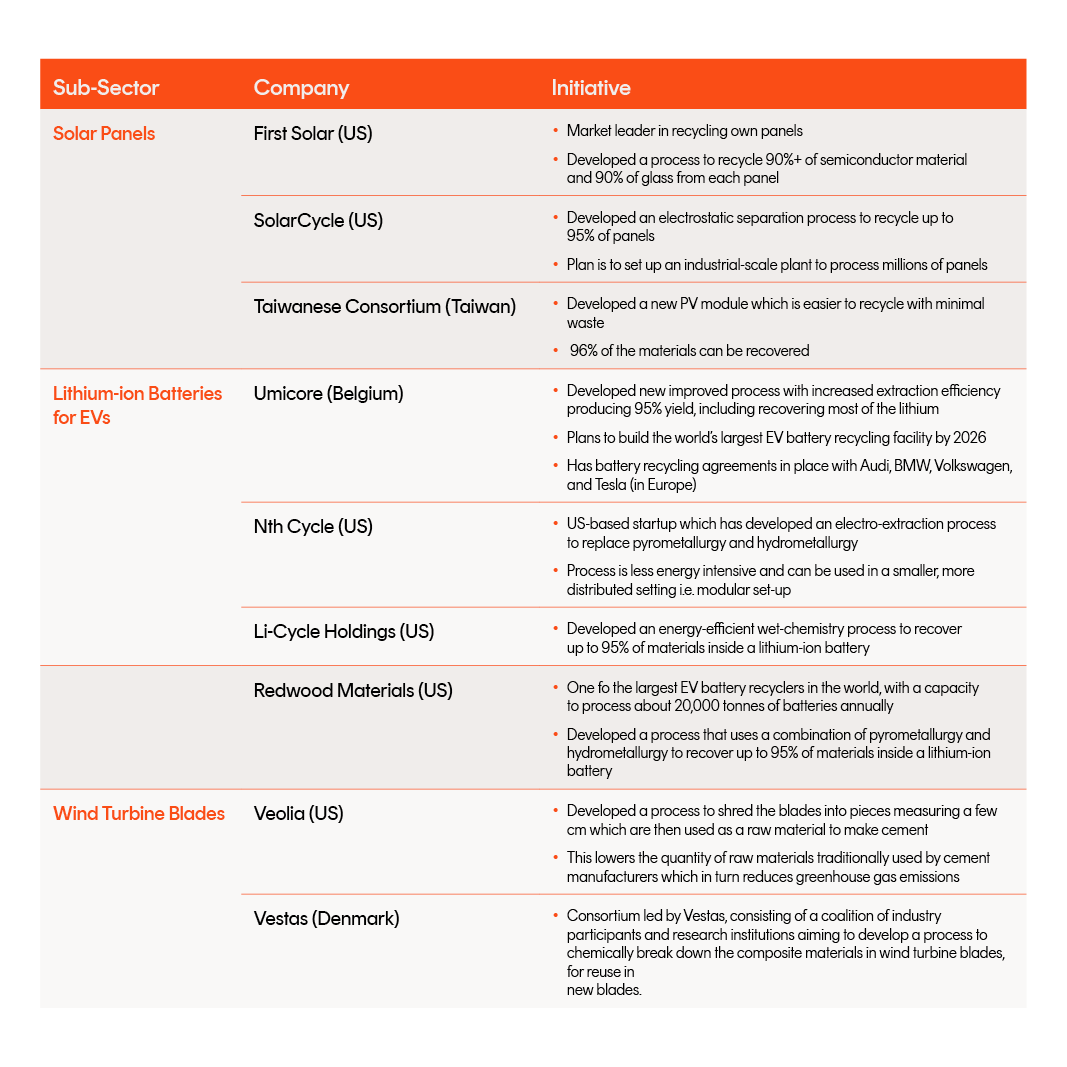

As the pace of adoption of renewables increases, and lack of recycling options come under the microscope, several startups, research institutions and private enterprises are venturing into this area, experimenting with new techniques which could make recycling profitable and scalable. Governments globally are also taking steps to establish regulations and guidelines for recycling renewables and encouraging the growth of a circular economy for renewables. For example, in December 2022, the EU reached a provisional agreement on recycling of batteries, that covers the entire battery life cycle, from design to end-of-life, and applies to all types of portable batteries sold in the EU, including batteries used in EVs and for industrial uses. The new rules target increased recycling and reuse and will require battery manufacturers to provide transparent information on the quantity of recycled materials in new car batteries by 20279.

We have highlighted some of the initiatives below:

What does the future hold?

It is almost indisputable that green energy will drive the energy transition over the next few decades. This scenario bears many positives, though it is equally clear we will have a waste problem on our hands if we do nothing. Australia alone is estimated to see a 40x increase in lithium-ion battery waste by 2036. The recycling industry for green energy is nascent but we expect it to gather momentum in the second half of this decade as many green energy installations installed during the last 10 years reach their end-of-life stage.

Betashares holds companies mentioned in this article across its ETFs (as at the date of this article). Umicore and Li-Cycle Holdings are held by the Betashares Energy Transition Metals ETF (ASX:XMET), which has substantial exposure to companies supplying and processing metals crucial to the net-zero transition. First Solar is a holding in Betashares Solar ETF (ASX:TANN), which provides exposure to a portfolio of the world’s leading companies in the solar energy industry. Umicore, First Solar, and Vestas are held by the Betashares Climate Change Innovation ETF (ASX:ERTH), which holds a portfolio of up to 100 leading global companies helping to address climate change and other environmental concerns through the reduction or avoidance of CO2 emissions.

Betashares Capital Ltd (ABN 78 139 566 868 AFS Licence 341181) is the issuer of the Betashares Funds. No assurance is given that companies noted above will remain in Fund’s relevant portfolios or will be profitable investments. Read the Target Market Determination and PDS at www. betashares.com.au and consider with your financial adviser whether the product is appropriate for your circumstances. The value of the units may go down as well as up. The Funds should only be considered as a component of a diversified portfolio.

Resources

1. https://www.irena.org/publications/2016/Jun/End-of-life-management-Solar-Photovoltaic-Panels

2. https://www.csiro.au/en/research/technology-space/energy/energy-in-the-circular-economy/battery-recycling

3. https://pubs.rsc.org/en/content/articlepdf/2021/ee/d1ee00691f

4. https://www.repository.cam.ac.uk/handle/1810/263878

5. https://industryeurope.com/sectors/transportation/kia-db-to-reuse-ev-batteries-for-energy-storage/

6. https://about.bnef.com/blog/lithium-ion-battery-pack-prices-rise-for-first-time-to-an-average-of-151-kwh/

7. https://blog.ucsusa.org/hanjiro-ambrose/the-second-life-of-used-ev-batteries/

8. https://americanbatterytechnology.com/what-will-it-take-to-recycle-millions-of-worn-out-ev-batteries/

9. https://www.europarl.europa.eu/news/en/press-room/20221205IPR60614/batteries-deal-on-new-eu-rules-for-design-production-and-waste-treatment

Written by

Vinnay Cchoda

Manager – Responsible Investments at Betashares, Ex Ellerston Capital and Venture Insights. Startup Founder and Strategy Consultant. Harvard Business School, University of Cambridge, and University of Mumbai. Passionate about climate change, sustainability, investments, and markets.

Read more from Vinnay.